Shear Modulus

Shear modulus measures how a material resists shape changes when a force is applied parallel to its surface. Imagine pushing the top of a stack of books sideways while keeping the bottom fixed – the books slide over each other, showing shear deformation. The shear modulus indicates how resistant a material is to this type of deformation.

Materials with a high shear modulus, like steel, are very rigid and hard, while materials with a low shear modulus, like rubber, are flexible and easily deformed.

Theory

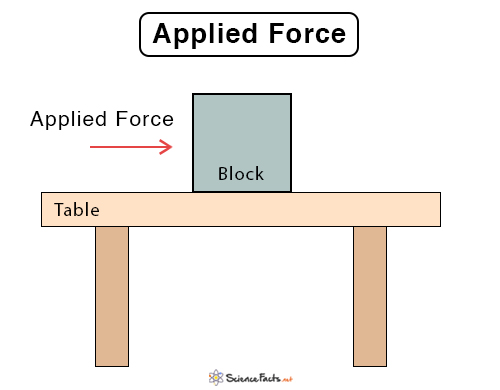

To understand shear modulus, we must first explore the concepts of shear stress and shear strain. Both describe how an object deforms when forces act parallel to its surface. For simplicity, consider a solid block (as shown in the figure).

Shear stress (τ) is the force applied per unit area in a direction parallel to the surface of the block. The following formula gives the shear stress:

τ = F/A

Where:

A: Cross-sectional area over which the force is distributed

Shear strain (γ) measures the deformation caused by shear stress. It is defined as the ratio of the displacement of one layer of the block to its original length. If the top surface of a block is displaced by a distance Δx while the bottom remains fixed, the shear strain is given by:

γ = Δx/h = tan θ ~ θ (for small θ)

Where:

h: Height of the block

θ: Angle of shear

Formula

Shear modulus, denoted by the letter G, is represented as the ratio of shear stress to shear strain:

\[\text{Shear Modulus} = \frac{\text{Shear Stress}}{\text{Shear Strain}} \\

=> G = \frac{\tau}{\gamma} \\

=> G = \frac{\frac{F}{A}}{\frac{\Delta x}{h}}\\

=> G = \frac{F \cdot h}{A \cdot \Delta x} \]

A higher shear modulus means a material is more rigid because more force (stress) is needed to produce the same horizontal displacement (strain). This is why the shear modulus is sometimes referred to as the modulus of rigidity.

To a first approximation, this type of deformation does not result in a change in volume; instead, atomic planes simply slide sideways over one another. Therefore, the area (A) (which determines the number of atomic bonds) is crucial in defining stress rather than just the applied force (F).

SI Unit and Dimension of Shear Modulus

The SI unit of shear modulus is the Pascal (Pa), which is equivalent to Newton per square meter (N/m2).

Since shear modulus is the ratio of stress (force per unit area) to strain (which is dimensionless), its dimensional formula is:

[G] = [Force] [Area]-1

=> [G] = [MLT−2] [L2]-1

=> [G] = [ML-1T−2]

Where M represents mass, L represents length, and T represents time.

Table of Shear Modulus Values

| Material | Shear Modulus (in GPa) |

|---|---|

| Rubber | 0.0006 |

| Polyethylene | 0.117 |

| Plywood | 0.62 |

| Nylon | 4.1 |

| Lead | 13.1 |

| Concrete | 21 |

| Glass | 26.2 |

| Iron | 52.5 |

| Steel | 79.3 |

| Diamond | 478 |

Relation to Other Elastic Constants

The shear modulus is closely related to Young’s modulus (E), bulk modulus (K), and Poisson’s ratio (ν). These constants describe different types of material deformation:

For isotropic (uniform) materials, the relationship between these constants is:

\[ G = \frac{E}{2(1 + \nu)} \\

K = \frac{E}{3(1 – 2\nu)} \]

Example Problems with Solutions

Problem 1: A metal rod is subjected to a shear force of 500 N over a cross-sectional area of 0.01 m2. The top layer of the rod shifts 2 mm while the rod’s height is 0.5 m. Calculate the shear modulus of the material.

Solution

Given:

Shear force: F = 500 N

Cross-sectional area: A = 0.01 m2

Lateral displacement: Δx = 2 mm = 0.002 m

Height of the rod: h = 0.5 m

The shear modulus (G) is given by:

\[ G = \frac{F \cdot h}{A \cdot h} \\

=> G = \frac{500 \text{ N} \cdot 0.5 \text{ m}}{0.01 \text{ m}^2 \cdot 0.5 \text{ m}} = 12.5 \times 10^6 \text{ Pa} = 12.5 \text{ MPa} \]

The shear modulus of the material is 12.5 MPa.

Problem 2: A 10 cm tall rubber block is fixed at the bottom and subjected to a shear force on the top surface, causing a 5 mm lateral displacement. If the rubber has a shear modulus of 0.8 MPa, calculate the shear stress acting on the block.

Solution

Given:

Height of the rubber block: h = 10 cm = 0.1 m

Lateral displacement: Δx = 5 mm = 0.005 m

Shear modulus: G = 0.8 MPa = 8 x 105 Pa

The shear modulus is given by:

\[ G = \frac{\tau}{\gamma} \\

=> \tau = G \times \frac{x}{h}\\

=> \tau = 8 x 105 \text{ Pa} \times \frac{0.005 \text{ m}}{0.1 \text{ m} = 40000 \text{ Pa} = 40 \text{ kPa} \]

The shear stress acting on the block is 40 kPa.

-

References

Article was last reviewed on Tuesday, February 4, 2025