Young’s Modulus

Young’s modulus measures the stiffness of a material when pulled or pushed. It measures a material’s resistance to shape changes under applied force. For example, a rubber band can easily stretch because it has a low Young’s modulus. In contrast, a metal wire, which is more resistant to stretching, has a high Young’s modulus.

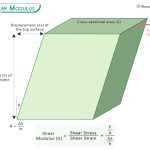

To understand Young’s modulus, we first need to define stress and strain. These fundamental concepts directly relate to Young’s modulus, as they quantify how a material responds to forces and deformation.

Stress

Stress is the amount of force applied to a material per unit area. It is calculated by dividing the force (F) by the cross-sectional area (A) of the material:

The cross-sectional area is the area of the material’s cross-section perpendicular to the applied force. The SI unit of stress is Pascals (Pa), which is equivalent to Newtons per square meter (N/m²).

1 Pa = 1 N/m2

Strain

Strain measures how much the material stretches or compresses compared to its original size. It is calculated by dividing the change in length (ΔL) by the original length (L0):

Strain has no units because it is a ratio of two lengths.

Young’s Modulus Formula

Young’s modulus combines stress and strain to give us a single value that represents how elastic or stiff a material is. It is the ratio of stress to strain:

This formula applies only when the material is within its elastic limit, meaning it will return to its original shape after the force is removed. The elastic limit is the maximum amount of stress a material can withstand without undergoing permanent deformation. Beyond this point, the material will not return to its original shape once the force is removed.

This relationship aligns with Hooke’s Law, which states that, within the elastic limit, the stress applied to a material is directly proportional to the resulting strain.

Units of Young’s Modulus

Since stress is measured in Pascals (Pa) and strain has no units, the SI unit of Young’s modulus is also Pascals (Pa). Young’s modulus values are typically large and are often expressed in gigapascals (GPa):

1 GPa = 109 Pa

Applications of Young’s Modulus

- Construction and Engineering: Steel is used in structures such as bridges and buildings due to its high Young’s modulus, providing strength and resistance to deformation.

- Sports Equipment: Carbon fiber is preferred in bikes, tennis rackets, and golf clubs for its high stiffness and lightweight properties, while flexible materials like rubber are used in shoes for better shock absorption.

- Automotive and Aerospace: Metals and alloys with high Young’s modulus are used in car frames and aircraft parts to ensure durability and safety under stress.

- Biomedical: Materials like titanium and certain polymers are chosen for prosthetics, implants, and medical devices because their elasticity matches the needs of the human body.

Table of Young’s Modulus Values

The table below shows the wide range of Young’s modulus values for various materials, indicating their differing stiffness. [3]

| Material | Young’s Modulus in GPa |

|---|---|

| Rubber | 0.01 – 0.1 |

| Low-density polyethylene | 0.11–0.86 |

| PTFE (Teflon) | 0.5 |

| Polyethylene terephthalate (PET) | 2.7 |

| Polystyrene, solid | 3 – 3.5 |

| Human Cortical Bone | 14 |

| Aluminum | 69 |

| Bronze | 96 – 120 |

| Brass | 100 – 125 |

| Steel (ASTM-A36) | 200 |

| Silicon carbide | 450 |

| Graphene | 1050 |

Example Problems with Solutions

Problem 1: A steel wire has a length of 3 m and a cross-sectional area of 5 x 10-6 m2. When a force of 600 N is applied, the wire stretches by 0.5 mm. Calculate the Young’s modulus of the steel wire.

Solution

Given:

Force (F) = 600 N

Cross-sectional area (A) = 5 x 10-6 m2

Initial length (L0) = 3 m

Elongation (ΔL) = 0.5 mm = 0.5 x 10-3 m

Young’s modulus (E) is given by:

The Young’s modulus of the steel wire is 719 GPa.

Problem 2: A copper rod of original length 2 m and cross-sectional area 1 x 10-4 m2 is subjected to a tensile force of 1000 N. If the rod stretches by 0.25 mm, calculate the Young’s modulus of copper.

Solution

Given:

Force (F) = 1000 N

Cross-sectional area (A) = 1 x 10-4 m2

Initial length (L0) = 2 m

Elongation (ΔL) = 0.25 mm = 0.25 x 10-3 m

Young’s modulus (E) is given by:

The Young’s modulus of the copper rod is 80 GPa

-

References

Article was last reviewed on Monday, February 3, 2025